What could be the strength of the business in the modern era? Strong supply chain operations support the firm stronger in overall business activities, by having collaborative planning across all the functions. By evaluating the current logistics operations, one of the hardest areas with several challenges in supply chain operations is processing cold chain products.

Processing cold chain consists of five major components such as manufacturing the temperature-sensitive product with accurate principles, storing the products in refrigerated warehouses, transporting the goods in refrigerated trucks or containers, safely distributing the products to end customers, and monitoring and controlling with real-time records to ensure the product quality per the compliance.

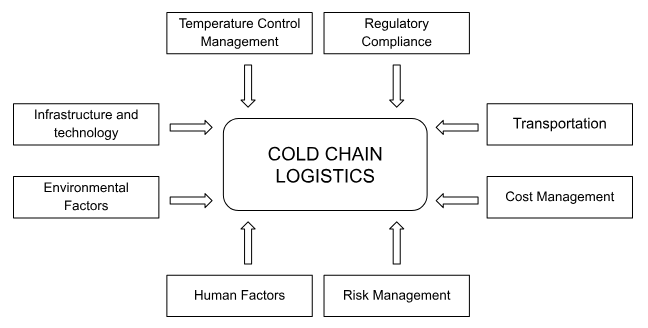

During this process in the cold chain there are several challenges faced compared to the general cargo, so let us brief the challenges in cold chain logistics in this article to take proactive measures in supply chain activities that will minimize the level of damage.

CHALLENGES IN COLD CHAIN LOGISTICS

1. Temperature Control Management

- Maintaining the product at a defined temperature throughout the supply chain, especially pharmaceuticals and perishable goods may spoil if the temperature varies

- Continuous monitoring of temperature in the overall process to comply with the compliance and traceability

- Need for refrigeration units that must work properly in transport and storage. Any malfunction can lead to a temperature fluctuation.

- To avoid failure, it is necessary to carry out regular maintenance and replacement of equipment as early as possible.

2. Regulatory Compliance

- Regulatory standards vary from country to country in cold chain logistics, especially in food and healthcare items and pharmaceuticals

- Obtaining multiple documentation from the authorities (FDA, NMRA, EU regulations, WHO standards)

- Maintaining the bunch of documentation for audit and whenever necessary

3. Transportation

- Ensuring the products reach their destination in appropriate transit time to avoid the cargo getting spoiled

- Delays caused in any circumstance (uncontrollable such as customs, bad weather, traffic, or geopolitical conditions) may corrupt the entire logistics and the cargo quality will be crucial

- Choosing the appropriate mode of transport by considering the cargo-specified temperature with the cost and time-effective method.

- Every transport has its specifications, such as packing, temperature, and handling

- The shipping cost of quick transportation is higher

4. Cost Management

- Operational costs for temperature-sensitive products are high compared to general cargo due to the special equipment and handling procedure

- Balancing the cost-effectiveness and the quality of the product is challenging in all aspects

- Cargo spoil and wastage due to temperature fluctuation leads to financial and resource loss

- Challenges in forecasting the demand considering the cargo condition and shelf life

5. Risk Management

- Always ready with robust contingency plans in case of any corruption in the shipment or handling

- Backup plans and transport methods in case of any disruptions

- Insurance costs are higher for temperature-sensitive products

- An adequate insurance policy needs to be chosen

6. Human Factors

- Train, educate, and expertise the employees on the temperature-sensitive cargo and its equipment, and continuous training and upgrading are necessary to prevent errors

- Effective communication is necessary among all the stakeholders in the supply chain to minimize the impact, simple error may lead to a huge impact on the business

7. Environmental Factors

- Adapt eco-friendly practices and technology to minimize the environmental impact of refrigerating and energy consumption

- Always consider operating sustainably by using the energy saver or optimized logistic routes in reducing carbon footprints

- Challenges in balancing the cost and efficiency

8. Infrastructure and Technology

- Limited availability of cold storage facilities in remote areas in several countries disrupts the SC operations

- Challenges in investing in infrastructure development due to high-cost

- Advanced monitoring of temperature and record tracking are necessary throughout the operation

- Integration of advanced technological systems such as GPS tracking, and IoT devices to establish proactive measures on time

- Challenges in competing with advanced technology such as Automated Storage and Retrieval Systems (to enhance the speed, minimal labor and space utilization)

Other than certain unavoidable challenges (such as shipment delays due to bad weather and geopolitical issues), disruption due to common challenges can be overcome by the advancement of technological platforms regularly. For instance, technological integration in IoT devices has real-time monitoring of the cargo condition to take proactive measures on time, Data analytics to act efficiently on optimized routes, and predictive maintenance, Blockchain strategy supports traceability and ensures product verification throughout the operations and temperature maintenance. However, obtaining insurance for every operation is the only proactive measure in minimizing the financial loss to the company.

Never miss a story from us, get weekly updates in your inbox.

Never miss a story from us, get weekly updates in your inbox.