The foundation of international trade is that shipping containers allow products to be transported across continents and oceans. However, in recent years, there has been an increasing concern about how the production and disposal of containers affect the environment. The creation and disposal of these massive steel producers present serious environmental concerns as global trade grows, from carbon emissions during manufacturing to the ecological effects of incorrect disposal.

Manufacturing Impact

Over 90% of the world's supply of containers is produced in China, which commands a commanding lead in this global business. Standard shipping containers are produced in large quantities by Chinese corporations like CIMC, DFIC, and CXIC. Even though they produce a lesser percentage, South Korea and Japan are experts in making high-end, cutting-edge containers, especially specialized and refrigerated ones. Vietnam is growing its market share in Southeast Asia, and India is enhancing its industrial skills. Both countries are emerging players in the region. Taiwan and the United States are two nations that produce customized containers for high-value commodities, concentrating on niche markets. In the meantime, South Africa, Malaysia, and Brazil all make regional contributions; South Africa specializes in customized and modified containers, Malaysia is expanding within the ASEAN region, and Brazil serves South America. This worldwide network meets a variety of demands in various regions by reflecting the container industry's mass manufacturing as well as its specialized needs.

Energy-intensive processes, such as the mining and processing of raw materials, especially steel, are involved in the manufacturing of shipping containers. One of the biggest contributors to industrial greenhouse gas emissions is the manufacture of steel. The World Steel Association estimates that in 2021, the manufacture of steel was responsible for 7–9% of the world's CO2 emissions. With a weight of about 2,300 kg, a normal 20-foot container requires a significant amount of energy and materials to build. This involves the extraction of iron ore, its smelting to produce steel, and its subsequent fabrication into the sturdy containers that are seen at ports all over the world.

In addition, the process uses a lot of water and produces other pollutants including nitrogen oxides and particulate matter that contaminate the air and water. For example, one ton of steel produced usually releases 1.85 tons of CO2, which means that producing one container can release more than 4 tons of CO2 into the sky. The annual production of millions of containers to satisfy the demands of international trade has a startling cumulative environmental impact.

Disposal Challenges

A normal shipping container has a lifespan of ten to fifteen years, after which it is either discarded or recycled. Disposal, however, raises environmental concerns. Even though a lot of them are converted into offices, apartments, or storage spaces, a sizable portion wind up in scrapyards. Disassembling and recycling a container uses a lot of energy and may cause dangerous substances like paint and insulation to leak into the surrounding air.

About 300,000 containers will have outlived their useful lives in 2023. A sizable fraction of these were thrown out or left unattended, especially in underdeveloped nations where recycling facilities do not adhere to international environmental norms. Because dangerous compounds drain out of improper disposal, it can contaminate adjacent water sources and soil.

Some disposal concerns have been lessened by the emergence of container architecture and other creative uses, but more work needs to be done to increase the scale to accommodate the annual retirement of a large number of containers. Additionally, the energy needed to adapt containers for new applications adds to their environmental impact..

Real-Time Data and Future Outlook

Recent evidence shows that people are becoming more conscious of and responsive to these environmental issues. For example, the shipping industry has been pushed toward greener standards by the International Maritime Organization (IMO), which includes using sustainable materials and cutting emissions during manufacturing. To lessen the impact on the environment by reducing the demand for raw materials, a new regulation was established in 2024 mandating that thirty percent of new containers be manufactured from recycled steel.

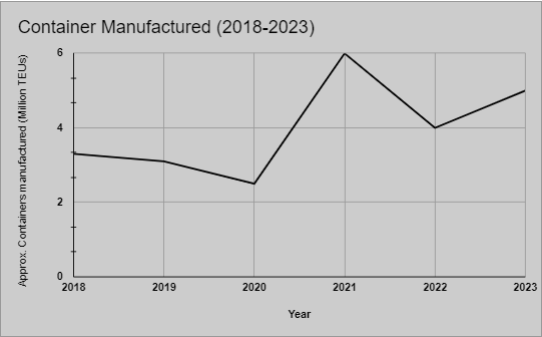

But the journey ahead is difficult. As the usage of shipping containers is predicted to increase by 4% annually, the World Economic Forum's 2023 report on global trade noted that attempts to reduce their environmental impact are falling behind. Innovations that face logistical and financial challenges are still in their infancy, such as the adoption of alternative, less carbon-intensive materials or biodegradable containers.

The production and disposal of containers have a substantial negative influence on the environment, which requires immediate action. Shipping containers will become more and more in demand as long as trade between countries grows. The environmental cost will only rise if manufacturing procedures and disposal methods aren't significantly altered. To lessen these effects and save the environment for future generations, the shipping sector, governments, and environmental organizations must collaborate to create and put into practice more sustainable procedures, from production to disposal.

Never miss a story from us, get weekly updates in your inbox.

Never miss a story from us, get weekly updates in your inbox.